Processing

Sample warping

One electronic, sectional drum warping machine enables us to manufacture warps with a maximum actual width of 360 cm and length from 35 to 1500 m. Length depends on a range of factors, including numbering, amount of threads and actual warp width. Even using only one cone we are able to produce industrial chains, including glued chains. This equipment's potential allows to manufacture designed warps with up to 128 colors without creel changing (creel changing will expand possibilities and make them endless).

Fractional warping

Four electronic fractional warping machines with working table from 220 cm to 280 cm allow us to maximize warp quality. Based on the item structure (numbering, amount of threads, length and designs), we select the most suitable machines to obtain even tension of the warping.

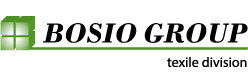

Sectional warping

Two electronic, manual warping machines and two automatic warping machines to weave raw or dyed yarns, both discontinuous twisted and continuous interlaced, twisted yarns. The temperature-controlled environment allows us to process critical items that might be highly electrostatic or particularly sensitive to humidity. We also succeed in manufacturing complex items like multi-fiber chains and pattern dyes. To avoid problems due to external factor contamination, discontinuous and continuous yarns are processed in completely separate places.

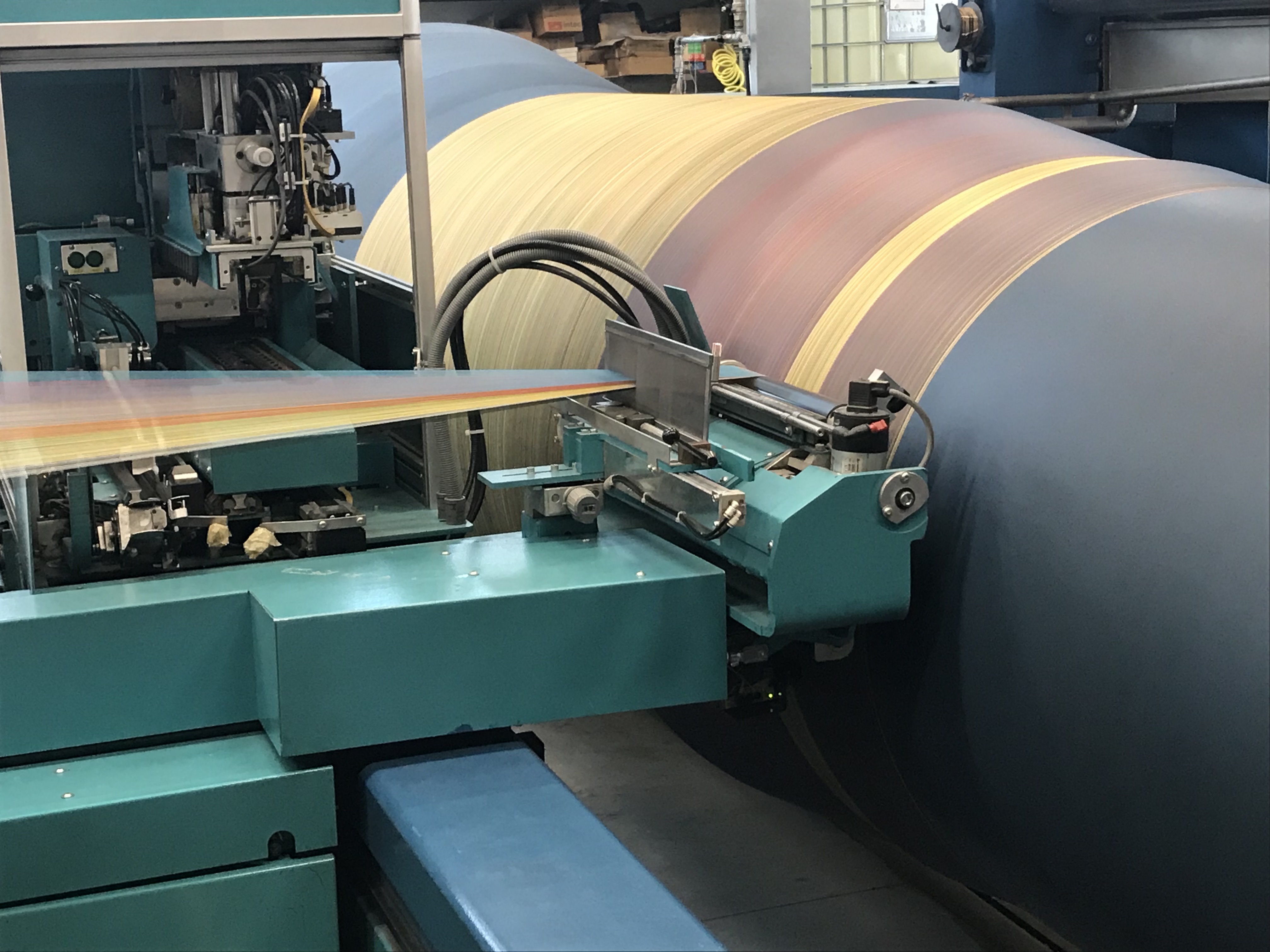

Sizing

Two electronic gluing lines with working table from 220 cm to 280 cm allow us to glue high density discontinuous items (with over 100 threads/centimeter) and guarantee full and even coverage of the warping.

Additional services

Hectic markets make it sometimes necessary to change the warp width, remove or add some thread, or simply replace the beam. We have a specific, dedicated machine for this kind of processes, which was studied and designed in cooperation with the manufacturer so to optimize operations and minimize waste with a final product in the medium high-quality range.